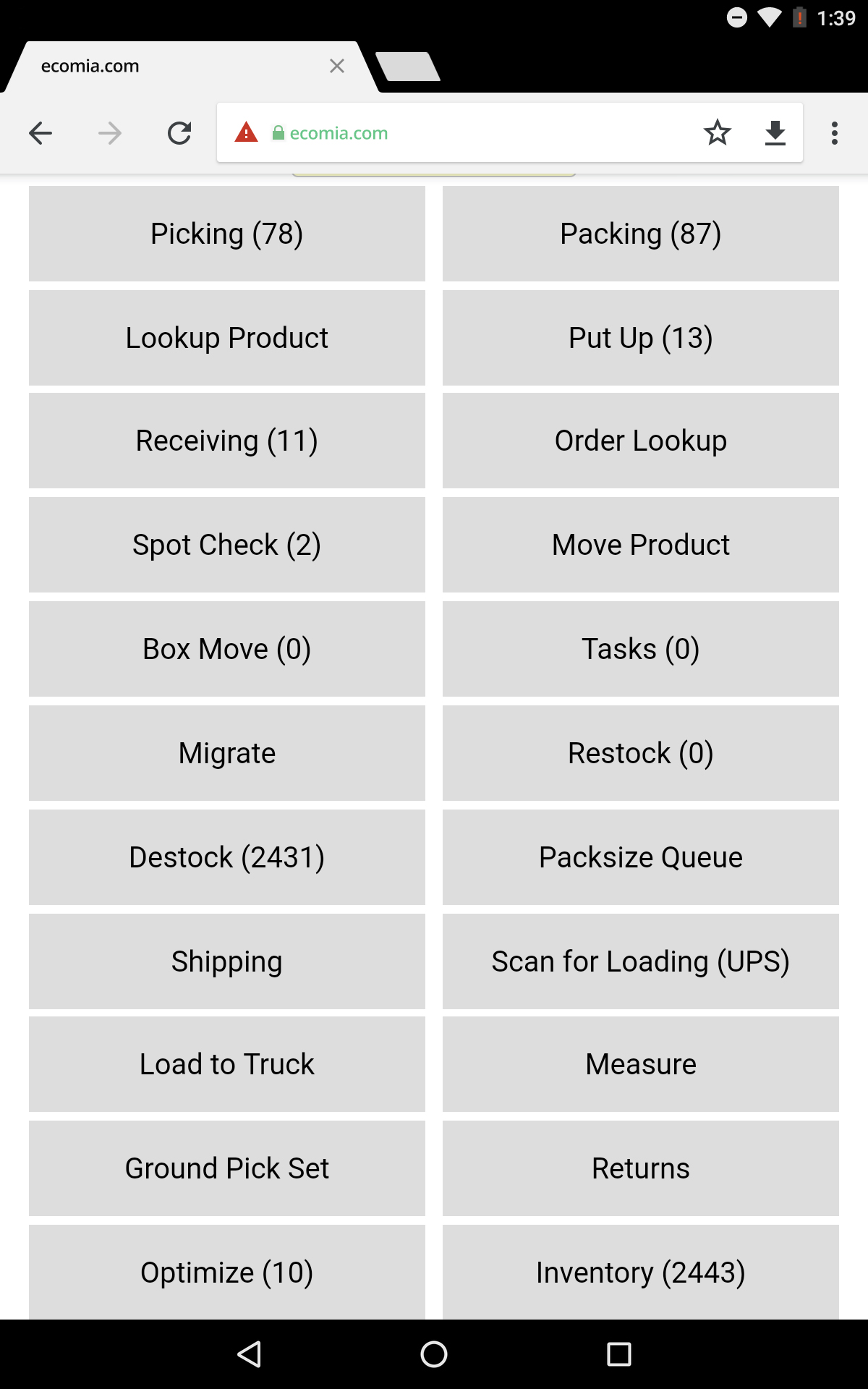

Ecomia’s warehouse management solution is a robust application in its own and consists of many modules and tools that can help you manage your warehouse and inventory with ease. Below are descriptions of some of the most essential modules that comprise Ecomia’s warehouse management.

Picking

As a quality-control step on the shipping process, picking items from bins during shipment is scanned every time as they are loaded on carts, totes or conveyors, letting the system know what is currently picked for that order.

Packing

Another quality-control step, packing items into a bag or boxes are scanned as well as they are awaiting shipment. Shipping label could be printed right after packing finishes, or, if you have additional requirements in the shipping process—like doing an assembly or build-per-order products—can use the final shipping step instead to print the label.

Shipping

Warehouse shipping employees use these to scan an invoice and print label after items have been packed. Ecomia marks the invoice as shipped and sends the tracking number associated with the shipment back to the corresponding marketplaces.

Load to Truck

As invoices are being marked “shipped” and the packages stuck with labels, warehouse employees scan the order and load the package to truck. Ecomia then marks the invoice as loaded and ready for pickup.

Lookup

When warehouse pickers could not determine what the product looks like, they can use this tool to see relevant information such as product image, bin locations, descriptions and other details relevant to warehouse management.

Order Lookup

Warehouse employees can scan an invoice to check shipment status, such as if it is completely picked and packed or shipped.

Returns

This is where authorized returns received by the warehouse are being scanned with the corresponding RMA document attached. Ecomia updates the number of items actually received against the quantity of authorized returns. Warehouse employees could also mark the condition of the item upon receipt.

Receiving and Put Up Stocks

When deliveries from vendors are received, they are being scanned in the receiving bays. Ecomia automatically updates the related purchase orders (PO) and marks them as received, while marking undelivered items as missed. When stocks are put up into bins, items are scanned again and mark the inventory as replenished with the added quantity. Ecomia then updates the related PO as complete.

Measure

A useful tool for measuring product dimensions and weights, including the packages they were packaged in when received from suppliers.

Restock/Destock

When stocks need replenishments or if an item has low velocity and needs to be moved out from more important bins, Ecomia shows you how much to restock or destock, and where to move respectively.

Spot Checks

Supervisors and managers can request warehouse employees to spot check inventory in the bins and do a count. Each item counted in the bin is scanned which enables Ecomia to compare what quantity is currently in the system against the spot check.

Move Product

When you need to move products from one bin location to another, this is the tool you need. As products are being moved, they are scanned so that movement will be reflected in the product history.

Pallet Move

For larger product movements of a particular SKU, or from moving products from another warehouse, pallet move is the tool to use. Ecomia intelligently tells you to move a number of pallets to the bins for stock replenishment.

Tasks

Warehouse employees can be assigned tasks that they need to do. These tasks are logged as they performed it, such as when they started and finished doing it. Supervisors has the ability to see the tasks done in the main administration section of Ecomia.

Time Clock

As warehouse employees come in to work and log into the warehouse application, they are automatically clocked in. Each action they do are logged, such as when they start picking invoices for packing and what last action they did during end of day. Ecomia also reminds them of lunch breaks, as well as count the remaining time in their breaks.